Hydraulic Manifold Systems

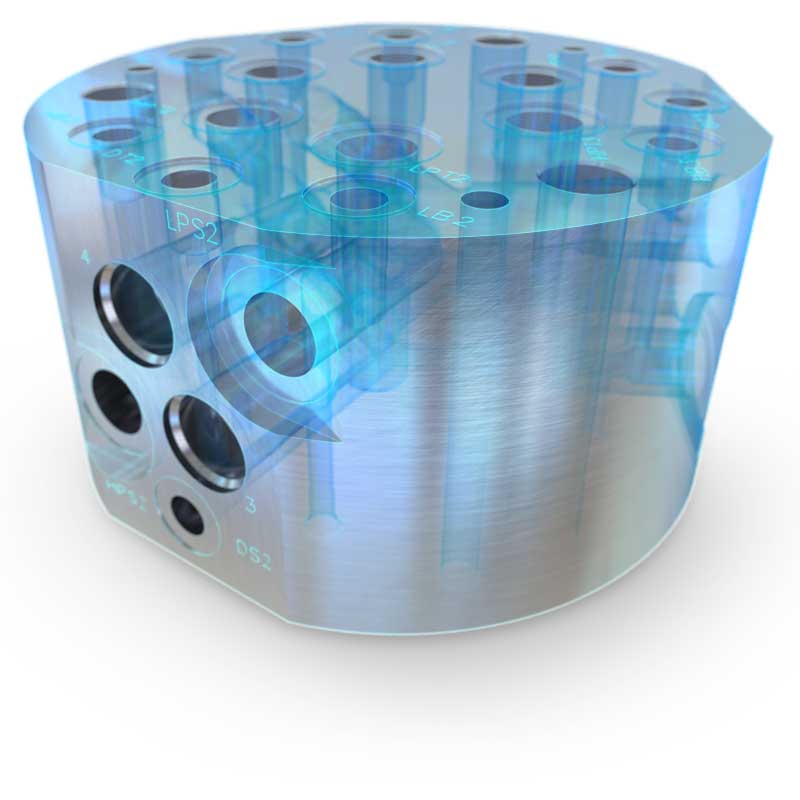

What is a Hydraulic Manifold?

A hydraulic manifold is a component within a hydraulic system used to regulate the flow of fluid which in turn controls the transfer of power between actuators, pumps and other components. The flow of pressurised fluid is controlled by hydraulic valves and directed to a working device such as a hydraulic cylinder or motor.

Energy Saving Manifold Design

Hydraulic manifold design has become increasingly important as the demand for reducing energy costs and improving efficiency continues to rise. Our skilled design engineers are experts in manifold design and can create systems to meet these demands. Optimised circuitry provides benefits in terms of reduced pressure drop and reduced heat generation, while reductions in weight and size aid installation and save space.

With the benefit of a shortened hydraulic flow paths, performance is boosted and machine control functions are enhanced. By reducing the number of hydraulic connections and the improvements to hose routing, hydraulic leakage is also greatly reduced. Our high-quality manifolds incorporate all of these benefits enabling considerable reductions in energy consumption and running costs.

Hydraulic manifolds benefit from being reliable, flexible and compact and by using multi-function cartridge valves it is possible to combine numerous control functions into a single manifold. The various states of the interconnected valves allow for complex control behaviours within the manifold. Upgrading or replacing valves can also be done easily with any down time reduced to a minimum.

Typical applications for hydraulic manifolds include heavy construction equipment, farm equipment, marine, off-highway equipment, material handling equipment and quarrying equipment.

Related Fluid Power is a market leader in the innovative design and manufacture of hydraulic manifold systems. Specialist application knowledge along with expertise gathered from the development of our large portfolio of cartridge and sub-plated mounted valves, allows us to offer our OEM customers control solutions that meet all expectations in terms of performance, quality and cost.

Product Scope and Control Options

• Manual, mechanical, pilot operated, electro-hydraulic, proportional

• Directional, pressure, flow, load-holding controls

• Typical Flows rates: to 600 lpm

• Typical Pressures: to 420 bar

• Large choice of voltage and termination options (incl. environmental proofed coils)

• Large choice of port sizes and types

• Manifold materials: High grade aluminium and steel

• Various protective coatings

Benefits of Hydraulic Manifold Systems

• Efficient and energy saving – large flow paths, minimised pressure drops

• Compact

• Ease of installation and maintenance

• Reduced Leakage

• Aesthetic

• Cost effective

• Simplified ordering

Manifold Design and Engineering

• Wide application experience

• Highly skilled engineering personnel

• ‘State of the art’ CAD system (2D & 3D)

• Hydraulic simulation software

• Prototype – manufacture, testing and validation

Manifold Manufacturing

• Multi-pallet CNC horizontal machining centres (24 hour x 7 day operation)

• Flexible Manufacturing System (FMS) software

• Small to large batch manufacturing

• Skilled assembly and test personnel

• Formalised processes throughout all operations BS-EN-ISO 9001:2008

Sales Support

• Wide application and product experience

• Aim to form close customer relationships

• Strive to achieve 100% customer satisfaction

• After sales backup and technical support

Please contact Related Fluid Power for more information.